Our Brands

Our Brands

Introducing our comprehensive selection of drainage products and solutions, available through our eight distinguished brands.

01.

01.

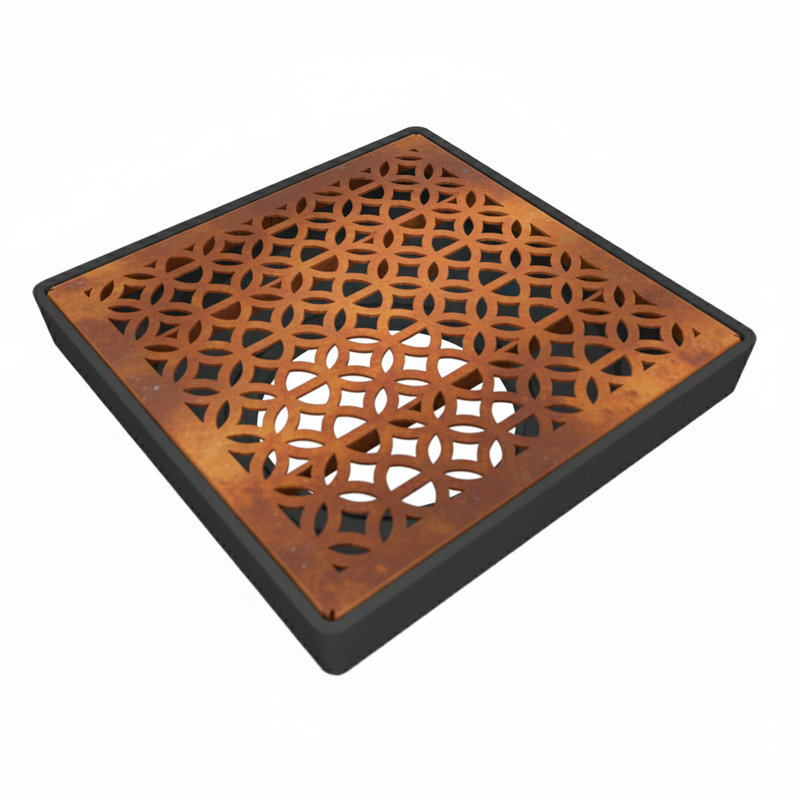

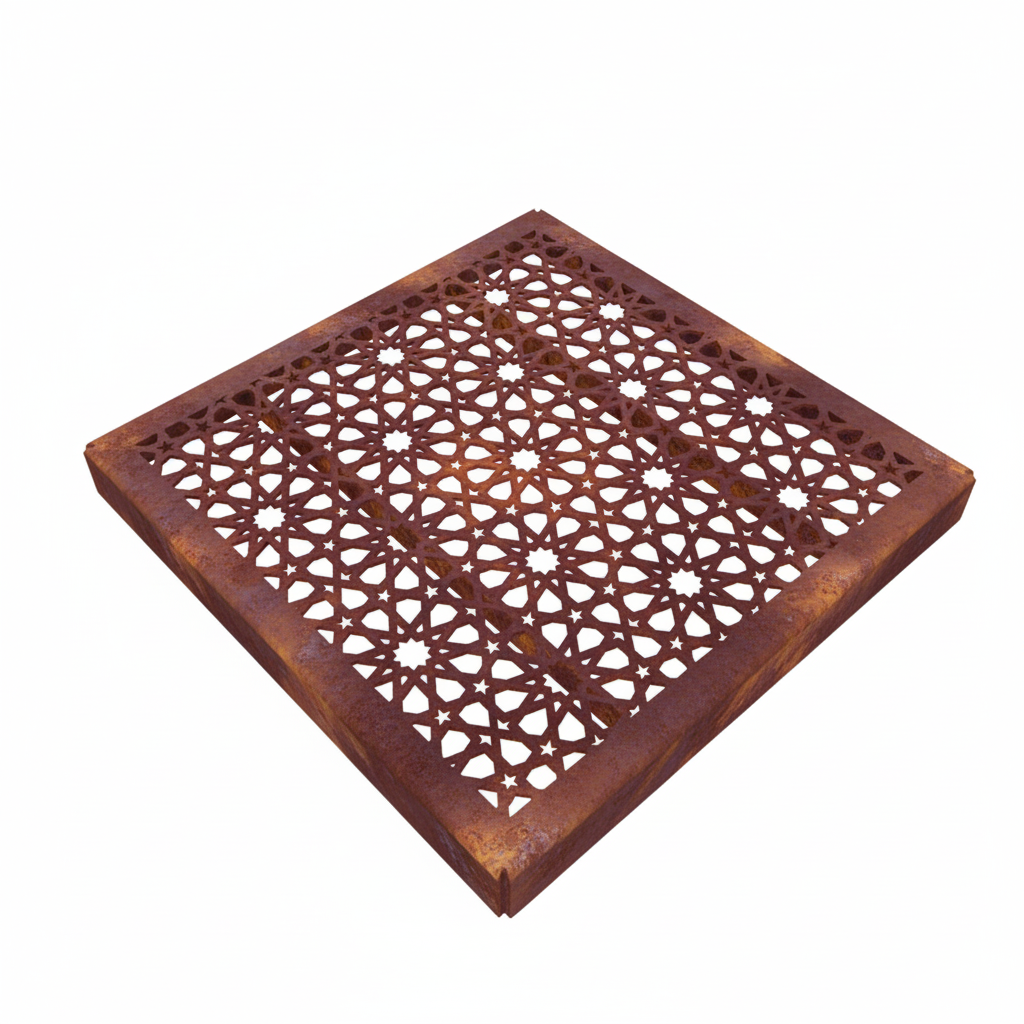

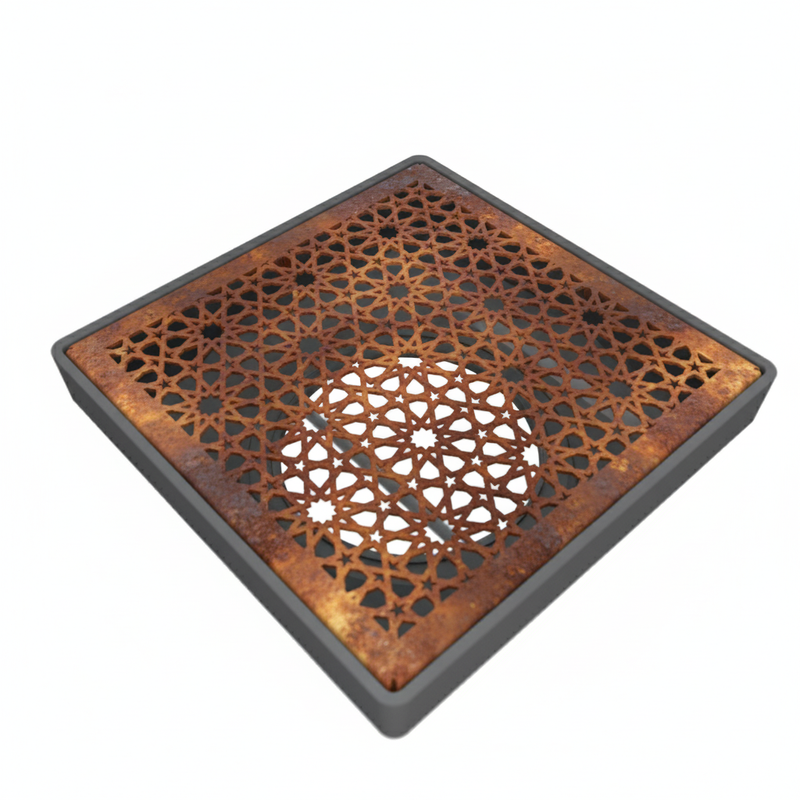

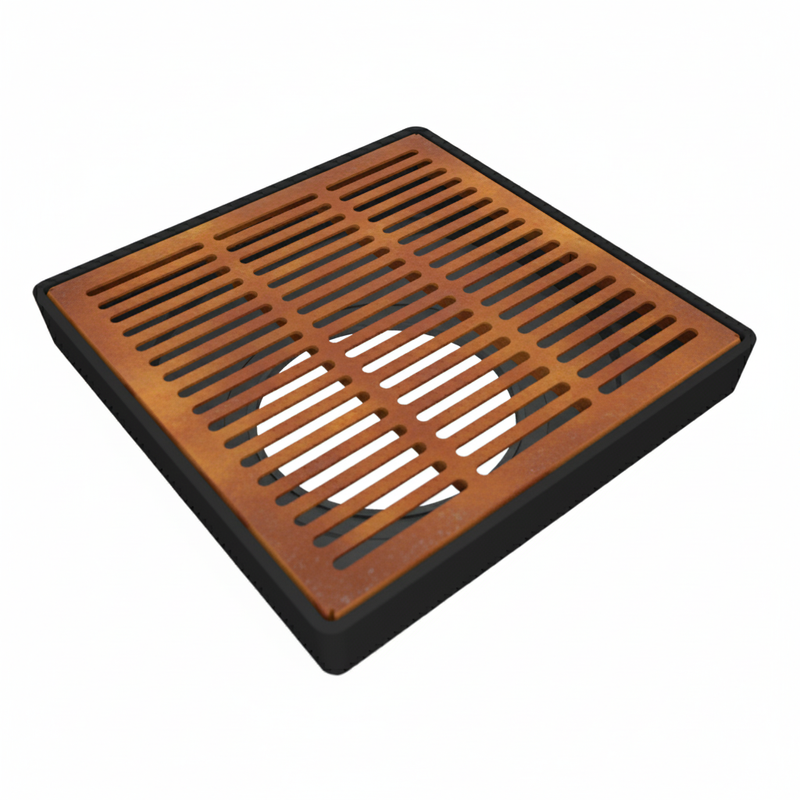

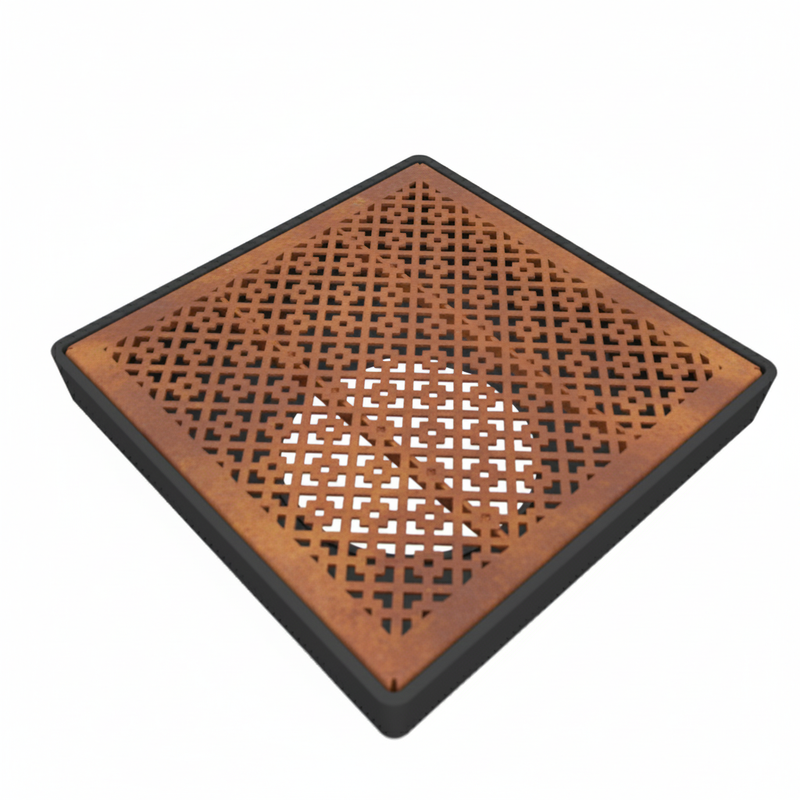

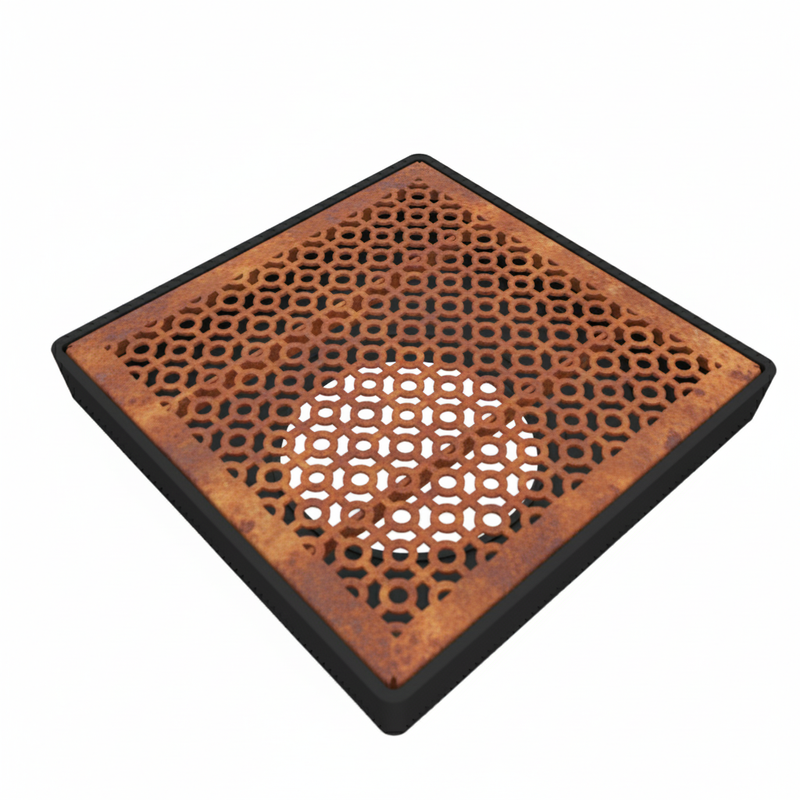

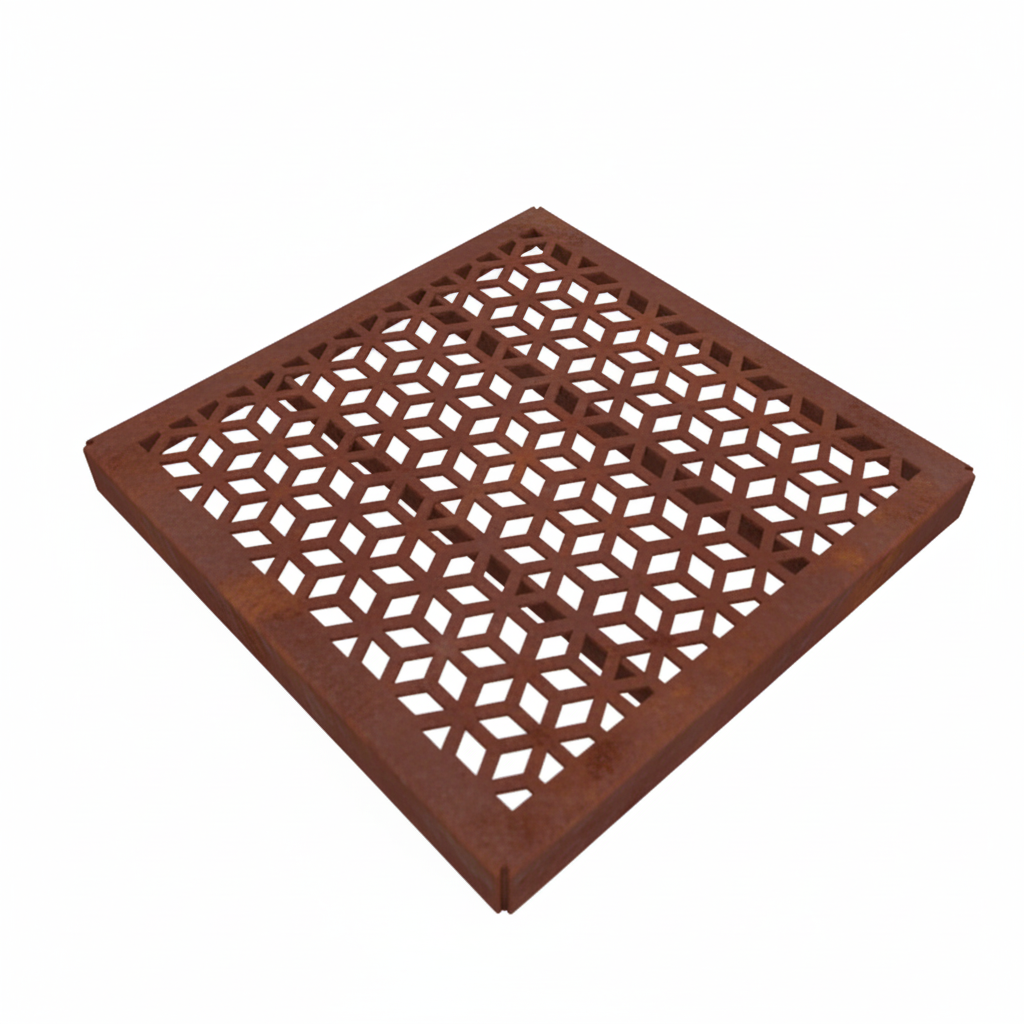

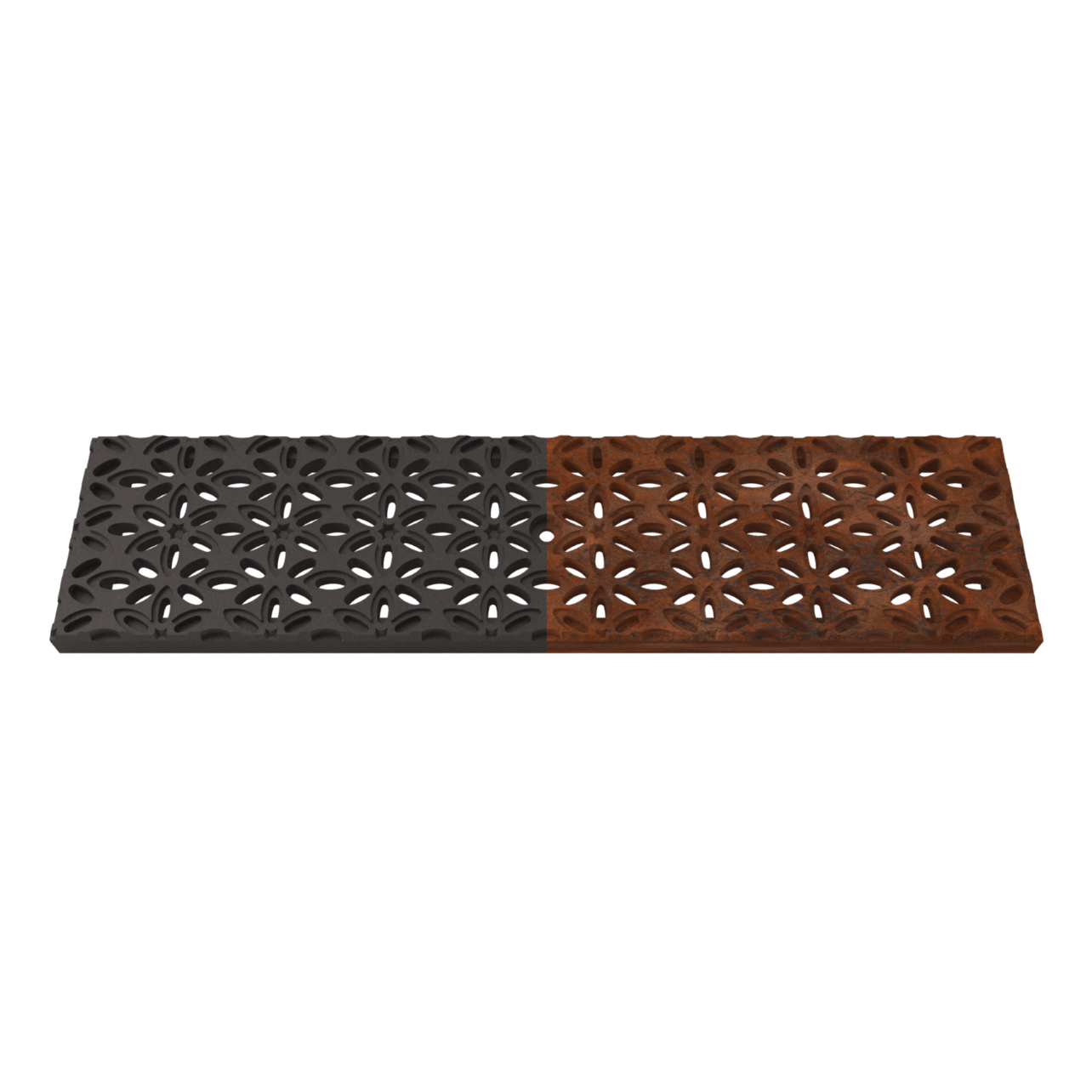

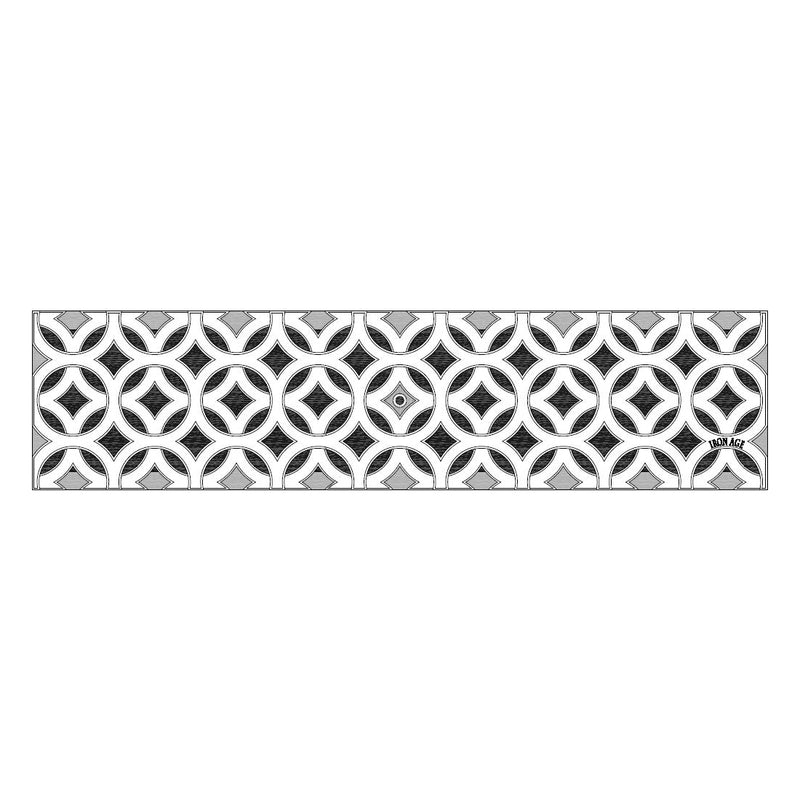

Our innovative decorative drainage products blend art and function, enhancing landscapes with stylish covers, grates, and channels, replacing traditional designs for both external and internal spaces.

02.

02.

Our threshold and patio uniflow drainage combines practicality and aesthetics, offering efficient water management, easy maintenance, and design versatility, enhancing the visual appeal of various landscapes.

03.

03.

Our award-winning, patented Aqualevel drain system protects buildings at door junctions, efficiently channeling water away. It outperforms traditional drains with its fully integrated, flush level design.

Our Company

Our Company

05.

05.

Our artisan-inspired designs and versatile materials create innovative street furniture and urban solutions, combining elegance and functionality to enhance public spaces with artisanal charm and nature-inspired sophistication.

06.

06.

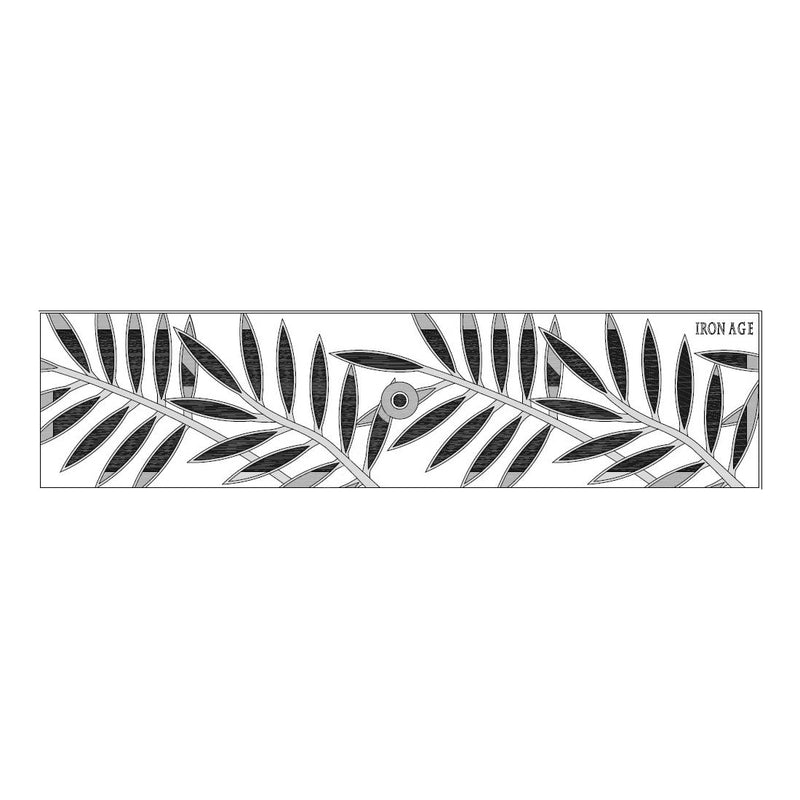

We offer elegant cast iron grates to reintroduce classic charm, perfect for traditional landscapes. Available in various widths, radius, and round or square gully covers. As well as street furniture.

07.

07.

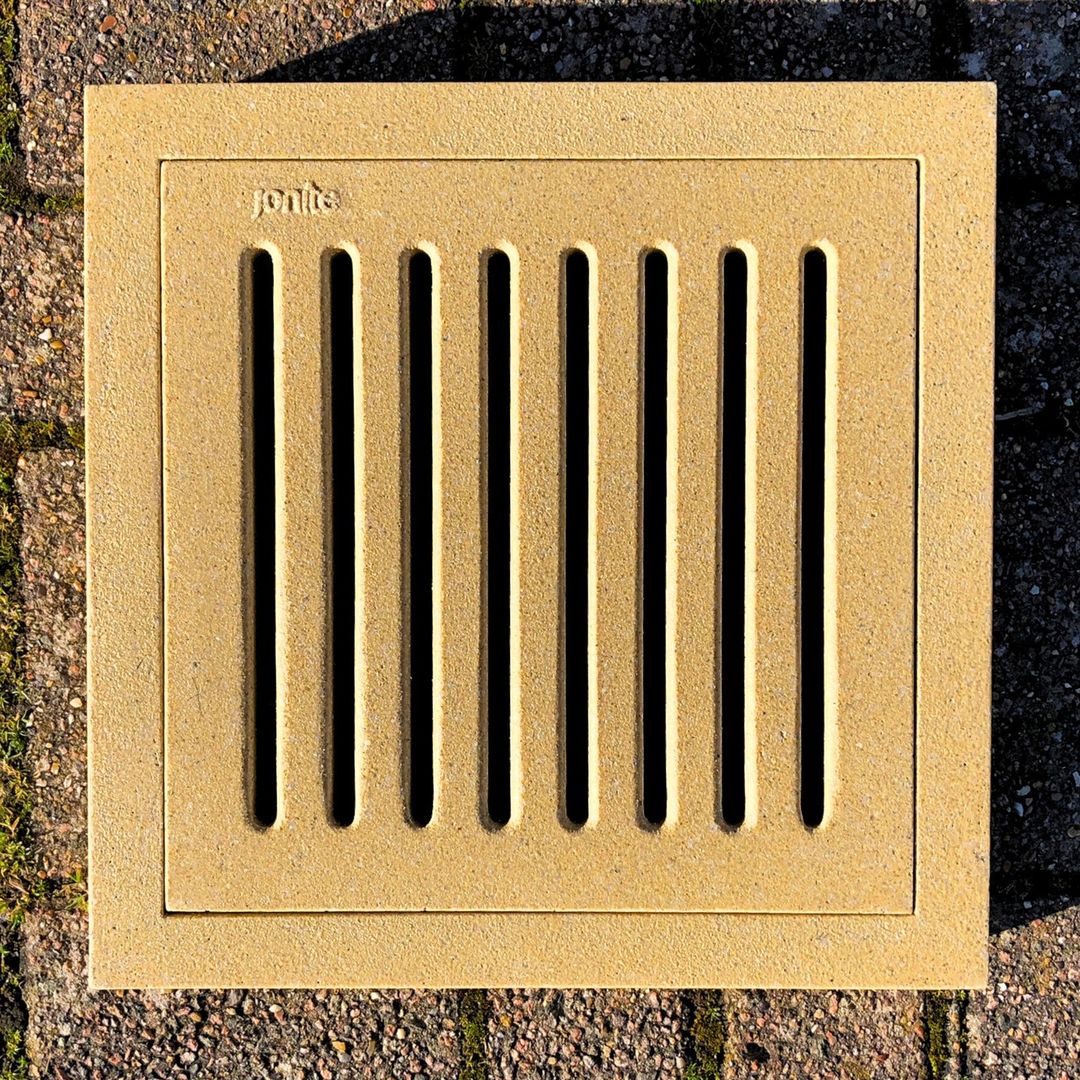

Reinforced, sustainable decorative stone gratings that combine beauty and strength for all projects. We offer grates, covers, benches, and grilles, enhancing commercial and residential spaces.

Why Rainwater Keeps Coming Under Your Patio or ...

The Hidden Weak Point Most Homes Share

If you've noticed rainwater sneaking under your patio or bifold doors, you're not alone.

Here's the thing, modern homes love clean lines and seamless transitions between inside and out. That's great for accessibility and design, but the moment you create a level threshold, you also create a potential flood path.

Even brand-new homes, built to high standards, are at risk because surface water doesn't care how new your doors are. It just follows gravity, and if that path leads toward your doorway, that's where it's going.

What this really means is: if your threshold isn't properly drained and sealed at design level, water will eventually find a way in.

Why Standard Drains Don't Actually Protect You

Let's break it down.

Most people think the standard and slim channel drains in front of their doors are doing the heavy lifting. They looks professional, collect a bit of water, and tick a box on the builder's list. But in most cases, it's not protecting you at all.

Here's why:

They're shallow. The channel often doesn't sit deep enough to deal with heavy rainfall or surface water that builds up.

They're open systems. Most cheap drains don't include any kind of water-stop barrier or pressure chamber. Once water starts to back up, it simply pushes through the slot and under your door.

They rely on ideal conditions. A light drizzle, clear outlet, and perfect paving gradient. Sure, they'll work fine. But in real weather, with blocked debris or uneven falls? They fail.

So even though it looks like you've installed drainage, it's mostly visual. The protection is an illusion.

The Physics of Surface Water

Here's what most people miss. Rain doesn't just fall, it flows. It travels across your patio or paved surface toward the lowest point. If your door threshold is the lowest spot - or even close to it - you've got a problem.

Once water pools, the pressure builds up. It starts forcing itself into tiny gaps and seams. Add in wind-driven rain and the natural “splash zone” that happens during a downpour, and suddenly your beautiful flush threshold becomes a direct entry point.

You can't see it until it's too late, damp carpet edges, swollen timber, or cold spots on the floor near the door. That's surface water ingress. And it's caused by design, not bad luck.

What Makes Aqualevel Different?

Aqualevel exists because no standard product could solve that problem. It's not just another drain, it's a complete threshold defence system engineered for true level access.

Here's how it's built differently:

Barrier Protection: Inside every Aqualevel unit is an internal water-stop chamber that prevents backflow. Even if water pressure builds in front of the door, it physically can't breach the barrier.

True Level Design: The system lets you achieve a completely flush, accessible threshold, without compromising waterproofing.

Controlled Fall System: The base channels are engineered to direct water precisely to the outlet. There's no guesswork in the gradient.

Stainless Steel Build: Every part is made from marine-grade stainless steel, so it doesn't warp, flex, or degrade like plastic or aluminium alternatives.

In short, it's a system designed to handle British weather, not brochure weather.

The Real-World Difference

Let's picture two identical patio doors in the same storm. The first has a cheap slot drain. Within minutes, the channel fills, the water starts bubbling up, and it overflows toward the threshold. By the time you notice, water has slipped under the frame.

The second has Aqualevel. As surface water builds, the internal barrier stops it dead. The system redirects it through the hidden flow channel and safely away to the outlet. The threshold stays dry, even when the water level in front of it is several millimetres higher than the slot.

That's the difference between “a drain” and “a defence.”

The Real Cost of Getting It Wrong

Once water breaches your door, the damage is immediate and progressive.

It seeps under flooring, lifts tiles, and can saturate insulation layers. Within weeks you can see swelling in door frames or soft patches in plasterboard. And because this isn't a burst pipe or internal leak, most insurance policies don't cover it.

A threshold flood can cost anywhere between £2,000 - £5,000 to put right. sometimes more if you need new doors. It's the kind of problem that always feels minor until the damage is done.

Why Aqualevel Is the Only True Solution

What Aqualevel does is simple: it takes a flaw in modern design and fixes it at the engineering level. It lets architects, landscapers, and homeowners enjoy that flush indoor-outdoor flow, but without accepting the usual flood risk that comes with it.

That's what we mean when we say “the only true level threshold drainage system in the UK.” It's not marketing language. It's literally a mechanical solution to a problem most products pretend doesn't exist.

Final Thoughts

If you've had water sneaking under your doors, don't blame your builder or your doors. The real issue is the drainage system in front of them.

Aqualevel is designed specifically to stop that permanently.

👉 Visit www.aqualevel.co.uk

to see how the system works and request a specification guide for your project. Protect your threshold before the next storm tests it.

How To Clean Your Channels & Drainage Covers

1. Channel Maintenance

Our drainage channels are designed for minimal maintenance, but an attention to detail can significantly extend their lifespan and functionality:

Debris Management: Regularly inspect the channel for debris, including leaves, twigs, or pebbles, and use a broom, shovel, or dustpan to remove them. For stubborn debris, employ a drainage hook or a robust clothes hanger to ensure unobstructed water flow.

Thorough Flushing: Employ either a garden hose or a pressure washer to systematically flush out residual debris or silt from the channel. This step is instrumental in preventing blockages and ensuring efficient drainage.

2. Stainless Steel Covers

Stainless Steel covers are renowned for their durability and corrosion resistance. A comprehensive maintenance regimen ensures their long-lasting allure:

Lifting the Cover: Gently lift the drain cover from the drain unit, taking care not to damage any surrounding elements.

Cleaning Routine: Clean the drain cover meticulously, utilising only a soft cloth or a soft-bristled brush soaked in mild, non-abrasive soap and lukewarm water. Steer clear of abrasive materials such as steel wool, which can mar the surface.

Polishing: Delicately polish the drain cover, following the brushed grain's direction. This practice preserves its exquisite finish and aesthetic appeal.

Combatting Lime Deposits: Should lime deposits surface, rely on common household descaling agents. Allow the product to work its magic for a few minutes before thoroughly rinsing with clean water. Avoid commercial cleaning products containing corrosive chemicals or bleach.

Corrosion Management: Stainless steel's remarkable resistance to corrosion hinges on its protective chromium oxide layer. It is imperative to steer clear of potent acids or chemicals like iodine, chlorine, fluorine, or bromine, which can compromise this protective layer and induce corrosion. Consistent cleaning is the key to warding off rust.

Handling Etched Products: For items featuring laser etching, ensure that you clean in alignment with the grain to maintain their pristine appearance.

3: Cast Iron Covers

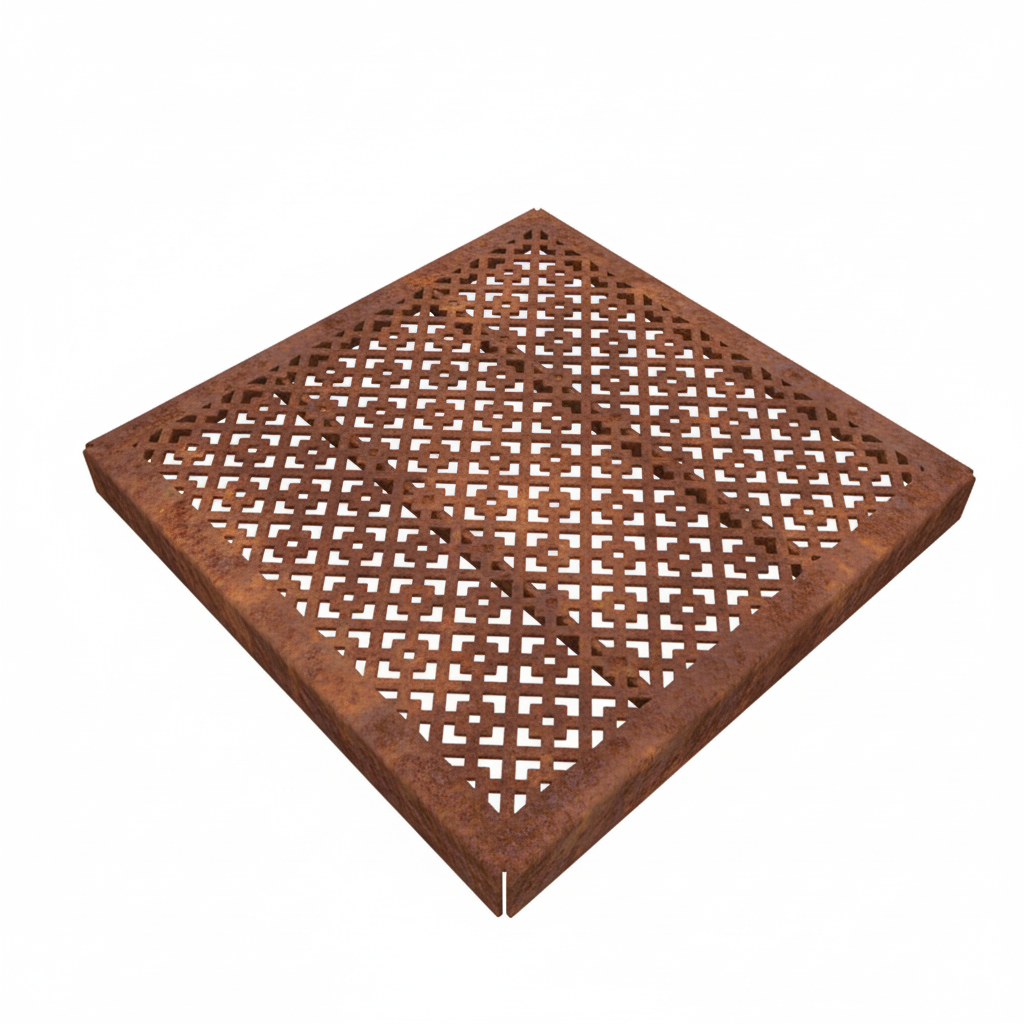

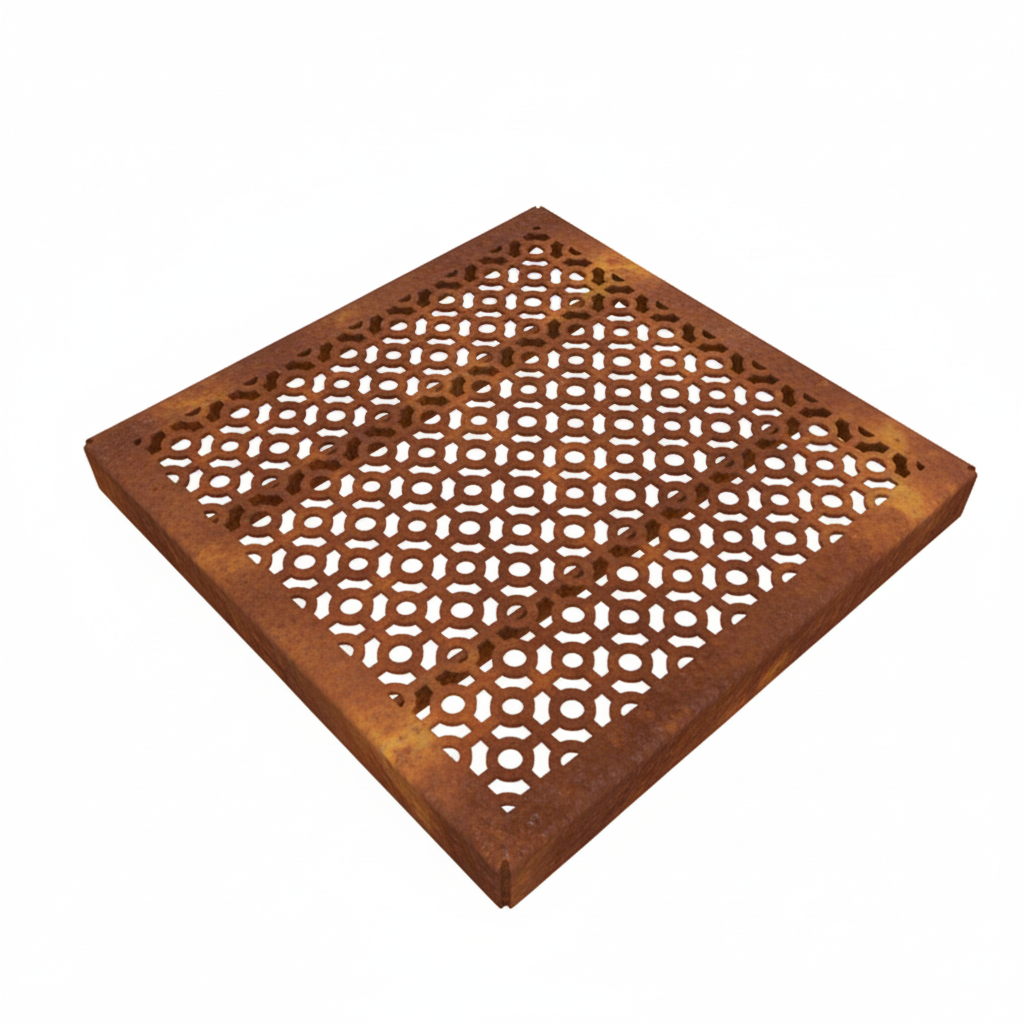

Cast Iron covers, while undergoing a natural oxidation process or rusting, can be preserved with a specific care regimen:

Understanding Oxidation: Cast Iron covers may exhibit some oxidation upon arrival. This initial stage initiates the creation of a protective Passivation Layer, which significantly slows further oxidation.

The Patina Formation: The Passivation Layer, often referred to as a Patina, imparts a distinctive chocolate brown hue to cast iron covers over time.

The Patina Evolution: The oxidation process evolves from a bright orange tint to a rich chocolate brown. Depending on environmental factors, this transformation may take approximately a year, culminating in covers that resemble traditional cast iron manhole covers.

Traffic-Induced Changes: Cast Iron covers in high-traffic areas may acquire a burnished appearance over time; however, unlike steel, they do not flake away, ensuring prolonged durability.

Protective Treatment: If your covers have been pre-rusted and treated by Lateral Design Studio, rest assured that the rusting process has been effectively halted, guaranteeing their timeless condition.

Maintaining your drainage covers and channels is an art form that requires precision and dedication. By meticulously adhering to these maintenance guidelines, you can relish your products for an extended period while preserving their aesthetics and functionality. Remember, overlooking maintenance can jeopardise the product's long-term integrity. For further inquiries or tailored support, please feel free to contact our dedicated customer service team.

Elevating Huf Haus Excellence: Custom-Made Stai...

In the realm of architectural innovation, there exists a German phenomenon known as the "Huf Haus." These stunning structures represent the perfect blend of contemporary design, sustainable living, and meticulous craftsmanship. To harmonise with the Huf Haus's unique construction requirements, Lateral Design Studio were tasked with a project to create and craft a custom-made stainless steel drainage grate and frame featuring our popular "Geo-Rectangular" pattern. A solution that would not only meet their strict perimeter building construction standards, but also provide easy access into the home, whilst enhance the aesthetic appeal of these exceptional homes.

What is a Huf Haus?

A Huf Haus is a type of prefabricated house of German origin, characterised by its distinctive post-and-beam construction and floor-to-ceiling glass facades. These remarkable homes are often built in harmony with nature, embracing energy-efficient design principles and sustainable materials. Each Huf Haus is a testament to precision engineering, and they are renowned for their modern aesthetics and minimalistic elegance.

Meeting Strict Perimeter Building Requirements

Huf Haus designs are not only aesthetically impressive but also known for their stringent Huf Haus building code. These codes often include specific requirements for continuous clear drainage troughs around the perimeter of the house, which is where our beautiful custom-made stainless steel drainage grates and frames come into play.

The "Geo-Rectangular" pattern on our drainage grate was specifically designed to complement the clean lines and geometric precision that are hallmarks of Huf Haus architecture. This pattern, characterised by a series of rectangles and shapes, adds an extra layer of sophistication to the exterior of these already striking homes.

One of the primary challenges faced during the construction of Huf Haus homes is ensuring that the construction drainage detailing seamlessly integrates with the architectural design. The wider and more intricate "Geo-Rectangular" pattern of our custom-made stainless steel drainage grate was created to not only enhance the aesthetic appeal but also to efficiently manage rainwater flow while providing easy access. This wider grille provides a more substantial surface area for water to pass through, reducing the risk of blockages and overflow during heavy rain, a common issue in regions with high precipitation.

The Benefits of Our Stainless Steel Drainage Grates

Aesthetic Appeal: The "Geo-Rectangular" pattern is a visually appealing addition to the exterior of Huf Haus homes, blending seamlessly with their architectural style.

Compliance with Regulations: Our drainage grates meet and exceed their strict perimeter building requirements, ensuring that water is efficiently managed without compromising the structural integrity of the house.

Durability: Crafted from stainless steel, this drainage grate is built to last, with a resistance to corrosion and wear, making it an excellent long-term investment for homeowners.

Efficient Drainage: The wider design of the grate allows for effective water drainage, reducing the risk of water accumulation, which can lead to structural damage over time.

Customisation: Each drainage grate is custom-made to fit the specific requirements of each Huf Haus project, ensuring a perfect fit and function and can have special powder coating finishes applied if required.